Vacuum Infusion Flow media and structural core

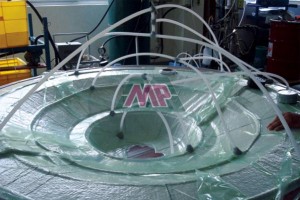

A concept unique to vacuum infusion is the idea of flow media. In VIP, resin enters the laminate at a fixed point (or points) and must be directed. Resin will always travel in the path of least resistance. Unfortunately, many reinforcements can provide a great deal of resistance that can prevent resin flow. Aiding the flow of resin is the job of flow media.

Although it is possible to infuse resin into reinforcement without the addition of flow media, it is rarely successful. The flow media is typically laid as a single layer between layers of reinforcement to provide an easy flow conduit for resin. This material ultimately becomes part of the laminate.

-

It provides the fastest infusion times. Constructed of randomly oriented, entangled PE filaments, this matting can typically move resin as fast it can be fed.

-

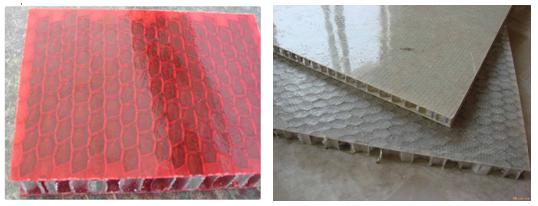

This material is similar to traditional vinyl foam cores, but includes grooves, perforations, and scores in the core material to help resin traverse the laminate while simultaneously adding strength and rigidity. Additionally, this material is on a scrim backing to aid conformability.

-

Vacuum Infusion Processing Works in Yacht Boat Manufacturing

Vacuum Infusion Processing Works in Fish Tank&Swimming Tank Manufacturing

Vacuum Infusion Processing Works in Machine Cover&Military Radar Manufacturing

Vacuum Infusion Processing Works in Wind Turbine Nacelle Cover Manufacturing

Message Sent

Thank you for your message, we will be in touch very shortly.

Sorry, there has been a problem and your message was not sent.

If you have any question,please enter your contact details below ! We will contact you as soon as possible !