Vacuum Bagging Peel ply

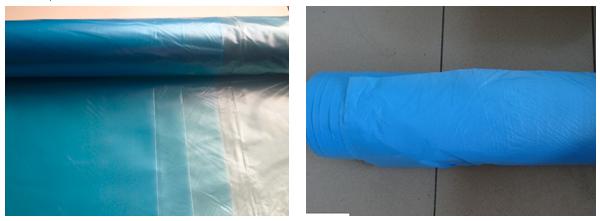

- Vacuum Bag – The vacuum bag encloses the part and applies a uniform pressure to the part surface. The bag must be flexible, tear resistant, non-porous, and compatible with the resin system. Nylon film in a thickness of .004 or .006 inches is the most commonly used material. More information is available in our Advanced Vacuum Bagging Techniques guide.

- Peel Ply – Peel Ply is an extremely strong, porous, treated nylon or polyester material. It eliminates the need for sanding or grinding when removed immediately prior to secondary bonding operations. In some cases, it can be used as bleeder ply to remove excess resin. It also prevents infusion lines and bleeder from sticking to the laminate. Peel ply is available as a release film, perforated film, or in textured/woven varieties.

-

Vacuum Infusion Processing Works in Yacht Boat Manufacturing

Vacuum Infusion Processing Works in Fish Tank&Swimming Tank Manufacturing

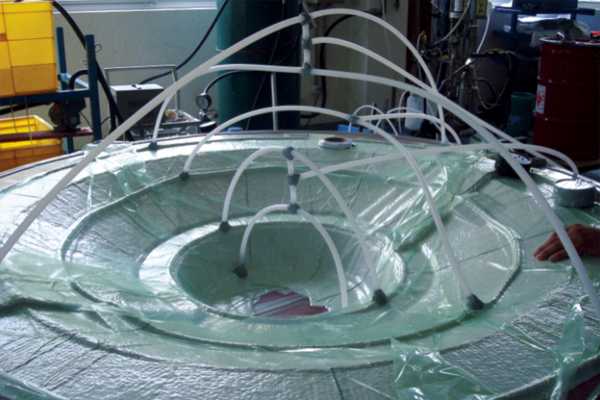

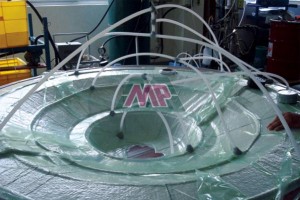

Vacuum Infusion Processing Works in Machine Cover&Military Radar Manufacturing

Vacuum Infusion Processing Works in Wind Turbine Nacelle Cover Manufacturing

Message Sent

Thank you for your message, we will be in touch very shortly.

Sorry, there has been a problem and your message was not sent.

If you have any question,please enter your contact details below ! We will contact you as soon as possible !