FRP Hydraulic Pultrusion Machine,FRP Hydraulic Pultrusion Puller

Brief Introduction

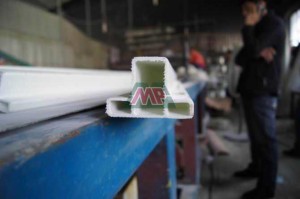

FRP Hydraulic Pultrusion Puller consists of heating up and molding the FRP raw materials in the die, then pulling out the molded material continuously to obtain the required FRP profiles under the alternative operation of 2 clamped tractive pullers.

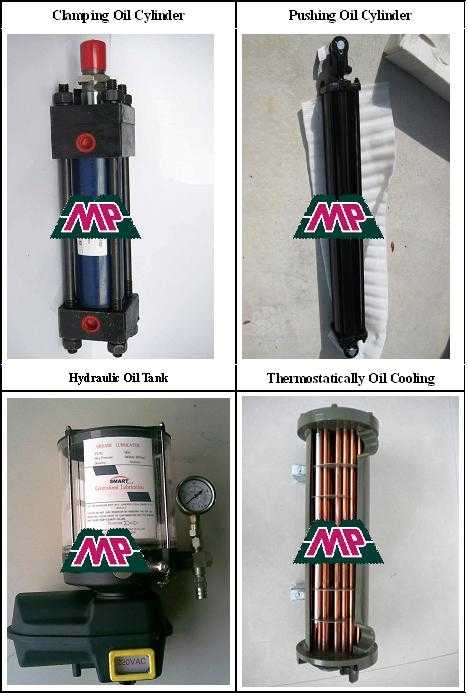

The machine is made up of the following parts: hydraulic clamped puller, electric heater, electric control box, pump station, pushing oil cylinder, clamping oil cylinder and optional device cutter, chopper and mixer. FRP pultrusion machine, with different kinds of moulds can produce different profile such as FRP pipes, rod, tube and etc.

-

-

1. Roving enter into yarn distribution plate. 2. Roving dipping and bathing the resin.

3. Surface veil and stitched mat come with rovings. 4. Group together by enter into regulation plate.

5. Through the regulation plate into molds. 6. Out of pultrusion molds,begin curing.

6. Cutting machine cut the profiles. 8. The pultrusion circulate by pulling grippers.

Message Sent

Thank you for your message, we will be in touch very shortly.

Sorry, there has been a problem and your message was not sent.

If you have any question,please enter your contact details below ! We will contact you as soon as possible !